Value Added

Most companies define Value Added as services that fall outside the core focus of the organization and while these services may be offered, they are most often provided at additional cost.

Per Wikipedia:

Value Added refers to “extra” feature(s) of an item of interest (product, service, person etc.) that go beyond the standard expectations and provide something “more” while adding little or nothing to its cost.

At AMT, we certainly offer services that complement our core business model, however, we define Value Added per the true meaning. “Go beyond” is the key phrase. At AMT, our standard conduct is defined by “going beyond”. It’s the seemingly little things we do that make a huge difference and end up not being so little after all.

Long before the buzz word, AMT instilled a culture of care and organization in our people and throughout our facility. We did not need weeks of training to do this – it’s a result of proper upbringing and those traits have carried over naturally. Tools, materials and equipment are stored in well labeled locations. It’s about efficiency and care – you will see it in our plant and you will experience it in our conduct.

Blue = Raw Material, Green = In-Process and Conforming, Yellow = Non-Conforming / Potential Rework and Red = Non-Conforming. These color coded bin standards in conjunction with computer generated labels fully identify Part Number, Job ID, and Part Status, along with other critical information. This assures that non-conforming product never gets mixed up and shipped to you, the customer.

Because only the best will do, AMT utilizes vibratory finishing where appropriate. This technique removes even the smallest of burrs, improves surface finish and prepares parts for post operations such as plating. This is just one more example of our relentless attention to detail and why the quality and cosmetics of our parts surpass those of our competitors.

Tired of receiving parts covered in coolants, machine oils and debris? Rest assured, AMT washes all parts using ultrasonic cleaning. Whether they are going for post operation special processes and plating or being shipped directly to our customers, our parts are clean and free of contaminates. From your receiving dock to your assembly floor, our parts are ready for use and require no addition cleaning.

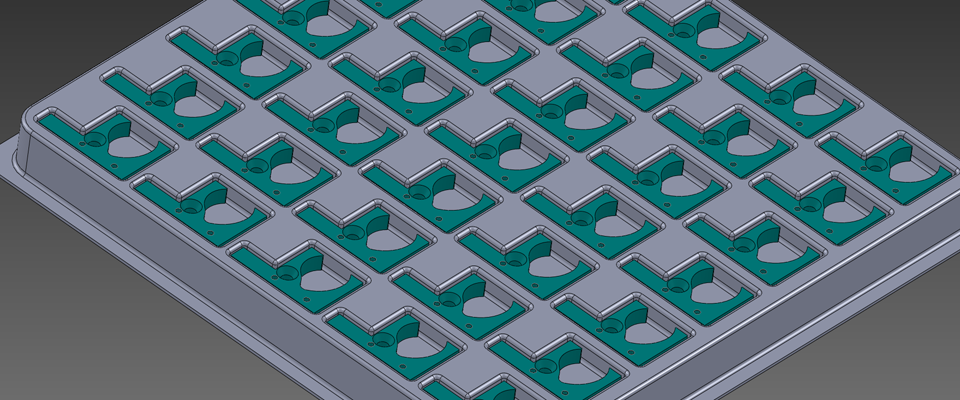

Most companies are looking for short lead-times and reduced inventory but none of this matters should the goods arrive on-time and are damaged due to poor packaging and handling. AMT rarely bulk packages product – in almost every case we use packaging trays (often custom), individual boxes, protective plastic netting or other materials to ensure the parts get to your dock in the same condition as they left ours.