Comprehensive Work Instructions

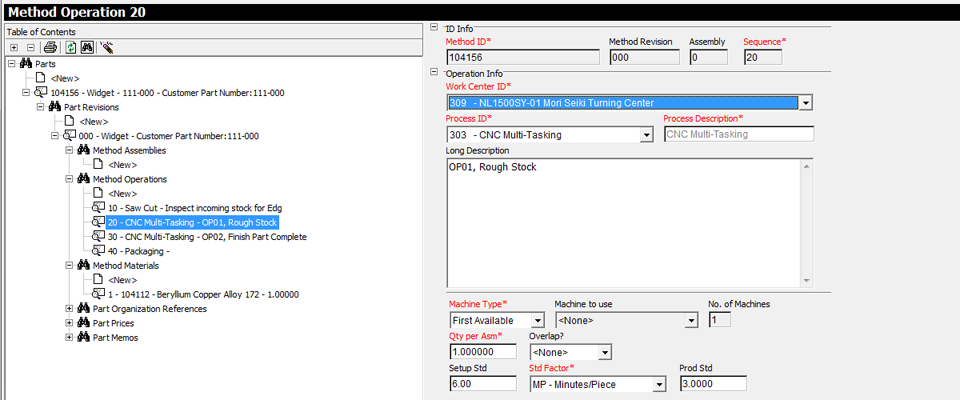

![]() Part prints are just not enough to convey all of the pertinent and critical information required to produce quality products on a consistent basis. AMT creates very detailed, process specific work instructions for each operation in the part routing, including, but limited to in-process and final packaging instructions.

Part prints are just not enough to convey all of the pertinent and critical information required to produce quality products on a consistent basis. AMT creates very detailed, process specific work instructions for each operation in the part routing, including, but limited to in-process and final packaging instructions.

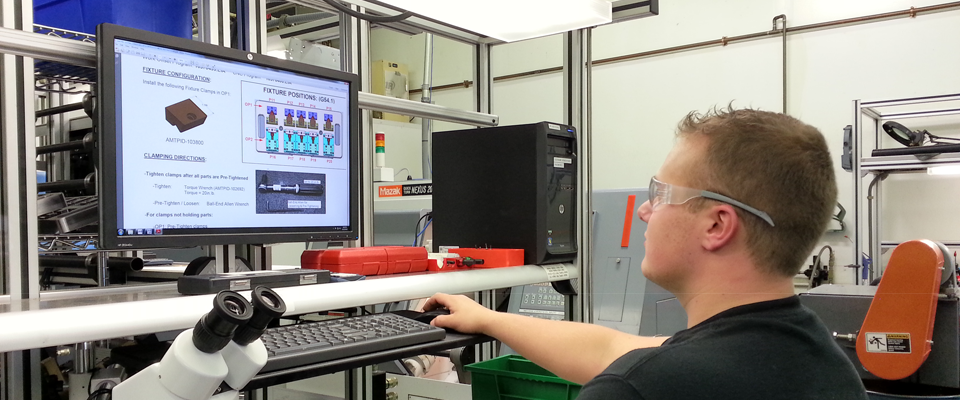

Extensive Use of Microscopes

![]() Along with final deburring, AMT has incorporated stereo microscopes at all work centers. 3.5X to 90X magnification allows operators to look over parts with extreme detail to locate and remove burrs and surface finish issues. As mentioned prior, relentless attention to detail is the only acceptable standard for the AMT team.

Along with final deburring, AMT has incorporated stereo microscopes at all work centers. 3.5X to 90X magnification allows operators to look over parts with extreme detail to locate and remove burrs and surface finish issues. As mentioned prior, relentless attention to detail is the only acceptable standard for the AMT team.

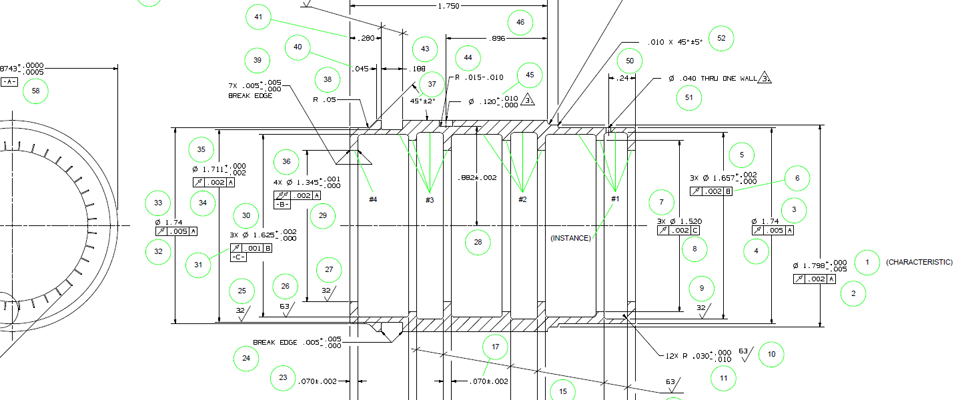

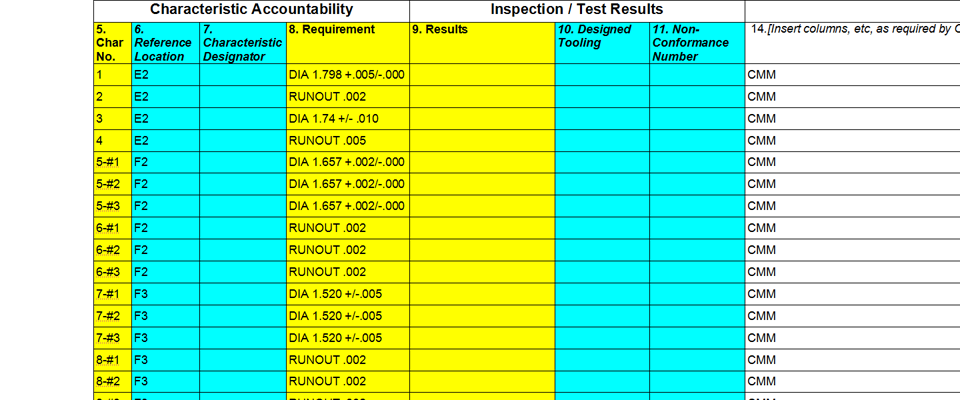

First Article Inspection per AS9102

![]() For several years AMT has performed First Article inspection in accordance with AS9102. We create very detailed, electronic balloon drawings and complete the AS9102 forms electronically. All data is stored on our internal server and backed up on and off site for an infinite period. We can retrieve inspection records within minutes.

For several years AMT has performed First Article inspection in accordance with AS9102. We create very detailed, electronic balloon drawings and complete the AS9102 forms electronically. All data is stored on our internal server and backed up on and off site for an infinite period. We can retrieve inspection records within minutes.