716-667-0778sales@amtny.com

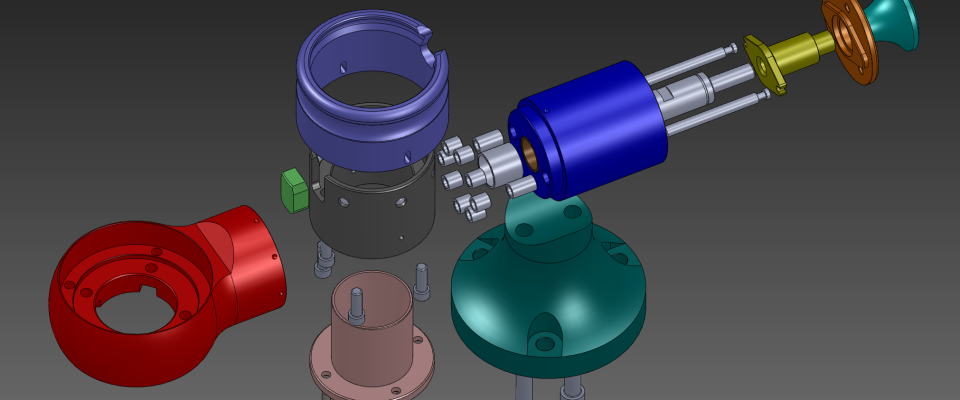

Prototype / Model Shop

To assist our customers, AMT offers prototype and model shop services for one-off parts, tooling and fixturing, and to assist in product development for production ready hardware.

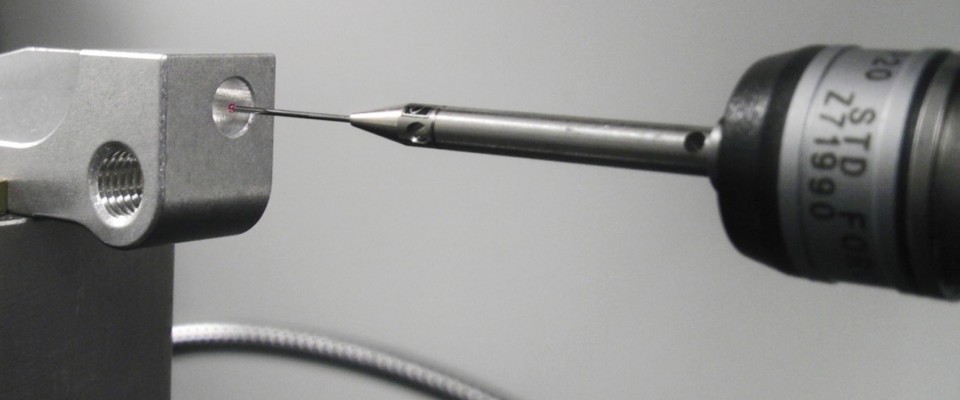

Capabilities

In addition to our inspection capabilities, our metal cutting capabilities include:

- Milling

- Turning

- Surface Grinding

- Small Cylindrical Grinding

Secondary and Post Process Operations

We have established long-term relationships with other vendors that partner with us for specific secondary and post process operations,such as:

- Wire EDM

- Sink EDM

- Large Cylindrical Grinding

- Jig Grinding

- Blanchard Grinding / Double Disc Grinding / Lapping

- Laser Cutting

- Sheet Metal, Fabrication and Weldments

Special Processes

We have extensive experience and long standing relationships with vendors that provide almost any special process such as:

- Anodize per MIL-8625, Type II, Class 1 & 2

- Black Oxide

- Chemical Conversion Coat per MIL-C-5541

- Electroless Nickel

- Hardcoat Anodize per MIL-A-63576A, MIL-8625, Type III

- Heat Treat and Stress Relieving

- Penetrant Inspect

- Shot Peen per AMS-S-13165

- Stainless Steel Passivation

Materials

- Aluminum: 2024, 6013, 6061, 7075, MIC-6

- Brass

- Beryllium Copper

- Stainless Steel: 17-4, 300 series, 420, 440

- Tool Steels: A2, D2, 01, S7

- Carbon Steels

- Acetal Copolymer (Delrin)